Multiple Packaging Testing Methods

With PRESTO package leak recognition, there are various packaging testing methods for you to guarantee the highest quality in seals, seams, closures and substrates are being met. The seal integrity test methods may change based upon the substituents of the package, but the PRESTO vacuum leak detection system provides all of these testing options with one machine.

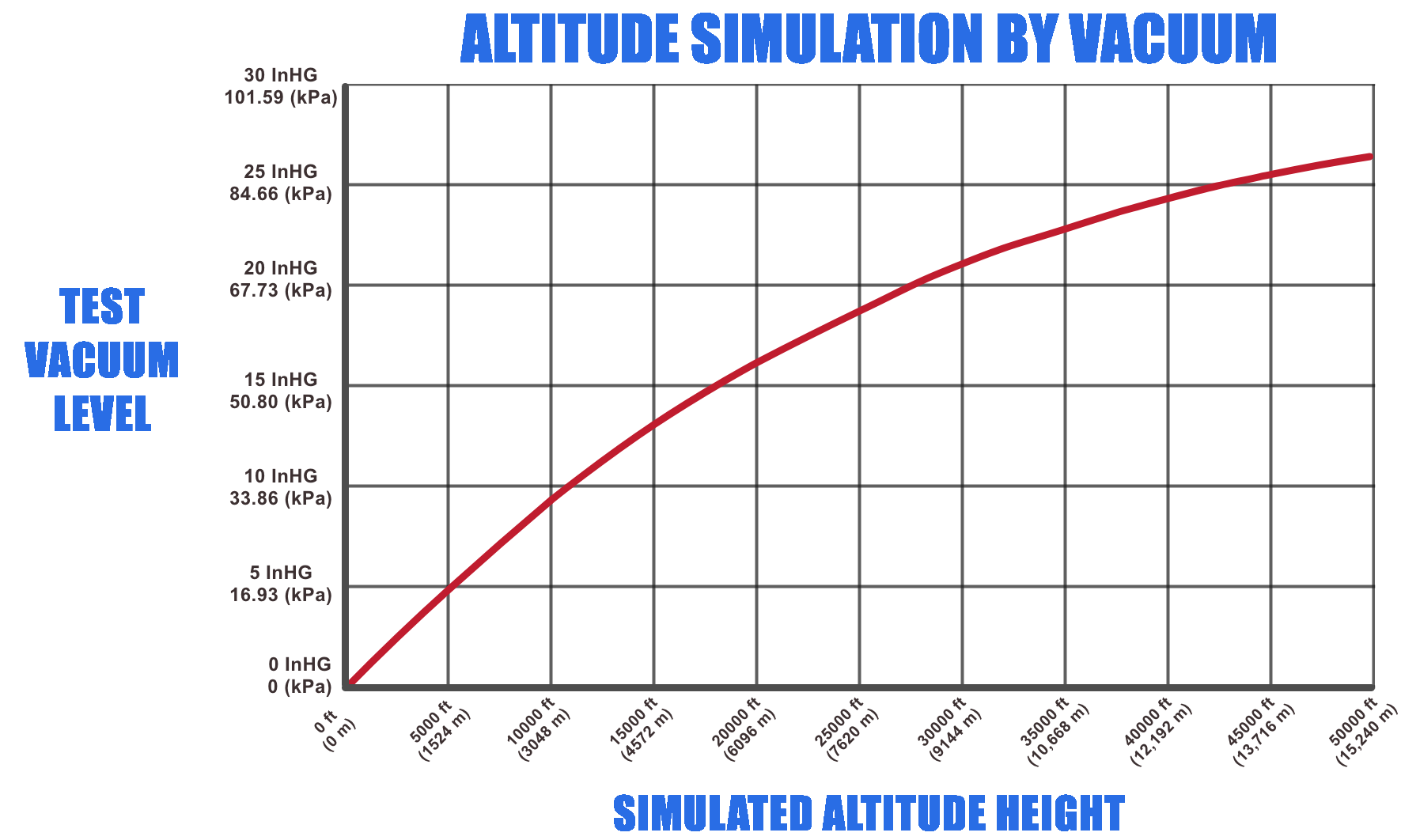

PRESTO vacuum style leak detector can be used to facilitate testing to standards such as ASTM D3078 (Bubble Test), , ASTM D4991 (Leak testing Empty Rigid Containers) ASTM D6653 (Altitude Test) , ASTM D4169, ASTM F2096, , and ASTM D5094 (Gross Leakage of Liquids with Threaded). Any package integrity test that needs a vacuum chamber, bubble test, or package pressure test can be done with the PRESTO vacuum seal integrity, vacuum tank, bubble leak detector.

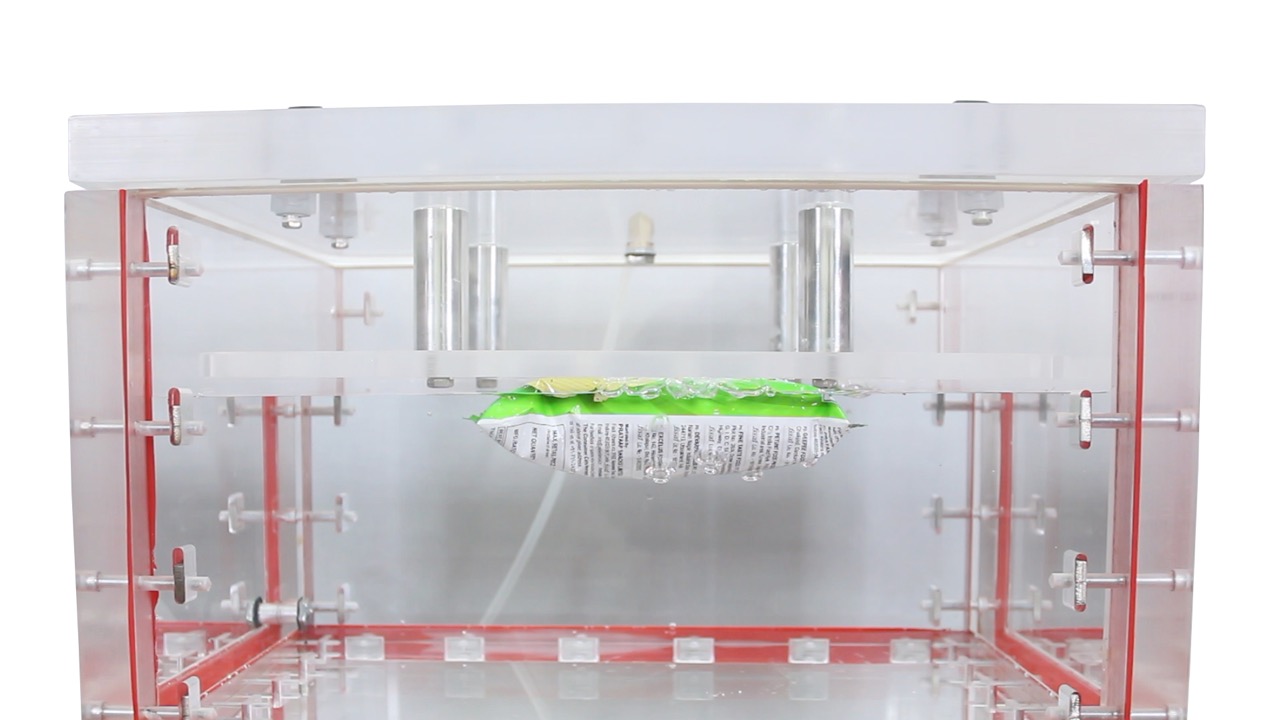

Bubble Emission Leak Test Procedure

Presto Bubble leak test process (ASTM Standard Test Method D3078-02) is excellent for packages whose contents have headspace or is filled with air or gas. After placing the package in the PRESTO LEAK DETECTOR, closing the lid, and submerging it under the water, a vacuum is drawn on the package; if air bubbles can be seen, it indicates that the package is compromised or faulty. By looking at where exactly the leak is you can do the needful to correct the problem. Many of the other leak detectors do not give a visual location of the problem thereby not allowing you to fix the problem! This test can also be used for any packet to determine the bursting point on the seal. The result can be used as a standard bench mark for regular Bubble Leak Tests in mass production, a trend can also be formulated in decreasing seal integrity. Changes & adjustments can be done to correct a mistake BEFORE it even happens!